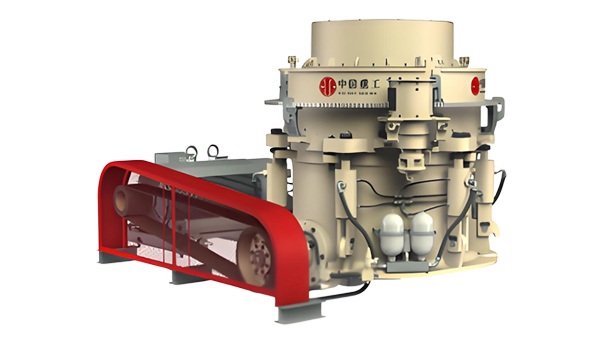

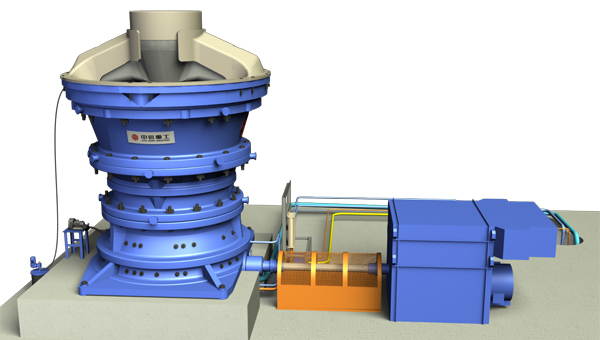

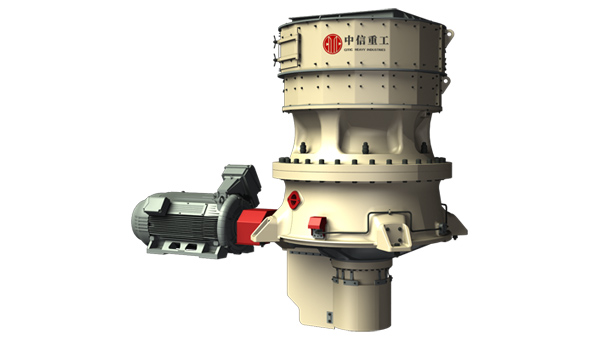

The CCS series single-cylinder cone crusher is widely used for secondary and fine crushing operations, with models catering to capacities from 500 to 1800 tons per hour. Integrated with our in-house designed and manufactured complete hydraulic lubrication station and AICS intelligent control system, these crushers ensure reliable operation while achieving intelligent control and highly efficient material crushing. The CCS series single-cylinder cone crusher reaches the advanced level of similar international products.

- Advanced curved crushing cavity: Provides optimal material flow, achieving high output and crushing efficiency.

- Constant crushing cavity design: Maintains a consistent cavity shape throughout the liner wear cycle for optimal and stable output and efficiency.

- AICS intelligent control system: Enables direct automatic adjustment of the discharge opening during operation and real-time automatic compensation for liner wear, resulting in stable crushing and controllable, uniform product particle shape.

- Super-strong structure and optimized design: Features a high-toughness alloy steel main shaft with special surface strengthening for extended fatigue life, and structurally enhanced upper and lower frames (over 50% stronger than traditional equipment).

- Excellent overload protection: Effectively passes uncrushable materials, protecting the equipment and reducing over 90% of failures caused by overload.

- New positive pressure dust-proof system: Multi-point input dust prevention technology maximizes dust exclusion from the crusher, ensuring the cleanliness of the lubricating oil.

| Model | Max. feed opening (mm) | Closed side setting (mm) | Mantle bottom diameter (mm) | Max. motor power (kW) | Capacity (t/h) |

| 215 | 8-40 | 1150 | 220 | 100-400 | |

| 275 | 13-50 | 1316 | 315 | 195~665 | |

| 275 | 16~51 | 1398 | 500 | 290~1125 | |

| 120 | 10~5· | 1398 | 500 | 168~525 | |

| | 350 | 10-70 | 1680 | 600 | 290-1500 |

| 425 | 13-70 | 2020 | 750 | 392-2195 | |

| 120 | 10-70 | 2020 | 750 | 305~1500 |

Note1: Actual production capacity depends on the actual processing circuit and ore properties. The capacity values above are calculated based on a bulk density of 1.6t/m³ and medium hardness ores.

Note2: The above parameters are for reference only and are subject to detailed engineering.

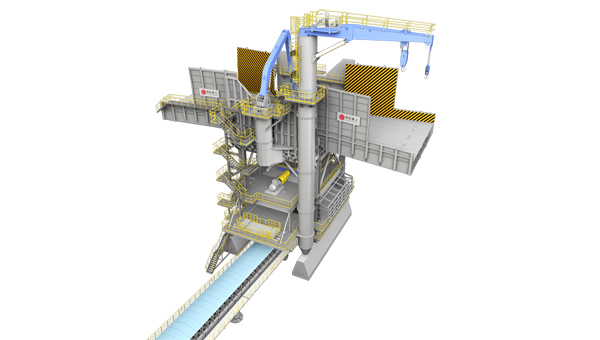

- Name of Client: Sinoma

- Project: Dapaikuang Project

- Location: China

- Crusher Model: CCS890

- Material: Granite

- Capacity: 30 million tons / year

- Year of Manufacture: 2022

- Name of Client: Hebei Xusheng Mining

- Project: Xusheng Mine

- Location: China

- Crusher Model: CCS895

- Material: Iron

- Capacity: 8 million tons / year

- Year of Manufacture: 2018

- Name of Client: Sichuan Anning Company

- Project: Titanium Project

- Location: China

- Crusher Model: CCS890+CCS870

- Material: Copper

- Capacity: 6 million tons / year

- Year of Manufacture: 2023

- Name of Client: Kungang Group

- Project: Dahongshan Iron Mine

- Location: China

- Crusher Model: CCS890

- Material: Iron

- Capacity: 5 million tons / year

- Year of Manufacture: 2024

- Name of Client: Ansteel Group

- Project: Waitoushan Iron Mine

- Location: China

- Crusher Model: CCS870

- Material: Iron

- Capacity: 7.5 million tons / year

- Year of Manufacture: 2021

-

Manufacturing

ManufacturingCasting and Forging Capacity

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively. -

Service

ServiceLifetime service

With state-of-the-art technology and rich experience, CITIC HIC works through each critical step to individualize the optimal process and performance as per customer needs. Our lifetime service covers equipment installation, testing, maintenance, refurbishing, remote monitoring & diagnosis, upgrading & retrofitting, and performance guarantee.