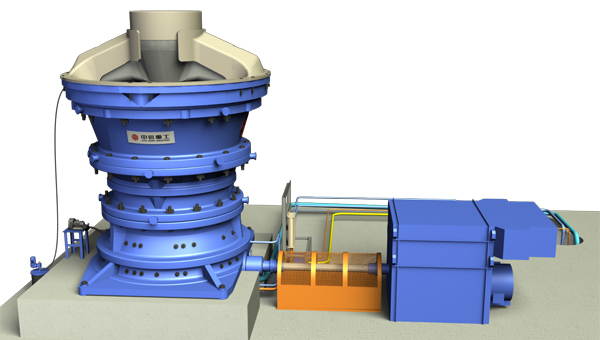

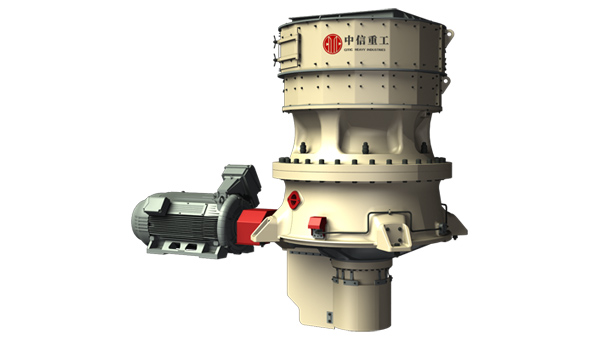

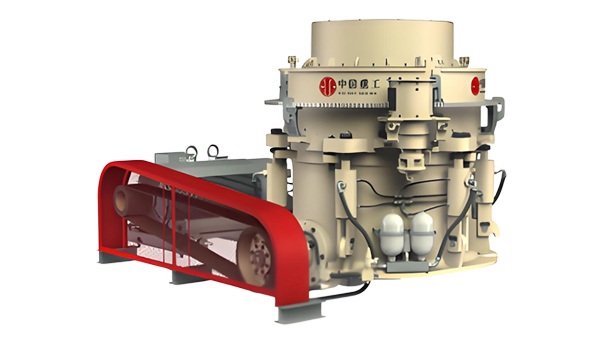

The CC series multi-cylinder hydraulic cone crusher is primarily used for secondary and fine crushing of various high and medium-hard materials. Featuring a large eccentric throw and high swing speed design, it delivers greater crushing force. Combined with an optimized cavity design, the equipment's processing capacity and crushing efficiency are enhanced, significantly improving the product discharge size and gradation, resulting in a higher rate of finished products with excellent particle shape, achieving the effect of "more crushing and less grinding," especially evident in fine crushing operations.

- Extremely large crushing locking force: Maintains a consistent discharge opening within a small, preset range, ensuring uniformity in crushed material.

- Optimal combination of eccentric stroke and high crushing frequency: Delivers superior crushing effects with a high output of fine material.

- Hydraulic adjustment and overload protection: The hydraulic motor drives discharge opening adjustments, ensuring efficient and easy control of the crusher’s output.

- Quick liner replacement: The hydraulic motor allows easy removal and installation of the liner, reducing downtime and improving operational efficiency.

- Automatic hydraulic protection system: Designed to protect the crusher from uncrushable materials by automatically releasing the pressure with no manual intervention.

| Model | Max. feed opening (mm) | Closed side setting (mm) | Mantle bottom diameter (mm) | Max. motor power (kW) | Capacity (t/h) |

| | 185 | 6-19 | 934 | 132 | 90-250 |

| | 235 | 6-25 | 1144 | 200 | 115-440 |

| | 300 | 6-30 | 1366 | 315 | 140-630 |

| | 351 | 6-30 | 1576 | 400 | 175-790 |

| | 331 | 9-30 | 1450 | 500 | 220-790 |

| | 356 | 9-32 | 1860 | 630 | 260-1200 |

| | 356 | 9-30 | 1860 | 710 | 341-1440 |

| | 384 | 6-32 | 2084 | 630 | 495-1935 |

| | 414 | 8-38 | 2380 | 800 | 615-2420 |

| | 64-414 | 10-38 | 2380 | 1000 | 700-3025 |

Note1: Actual production capacity depends on the actual processing circuit and ore properties. The capacity values above are calculated based on a bulk density of 1.6t/m³ and medium hardness ores.

Note2: The above parameters are for reference only and are subject to detailed engineering.

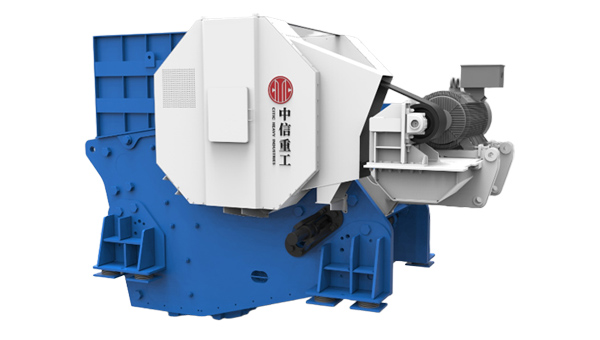

- Crusher Model: CC800M

- Motor Power: 630kW

- Quantity: 3

- Material: Copper

- Capacity: 20 million tons / year

- Year of Manufacture: 2024

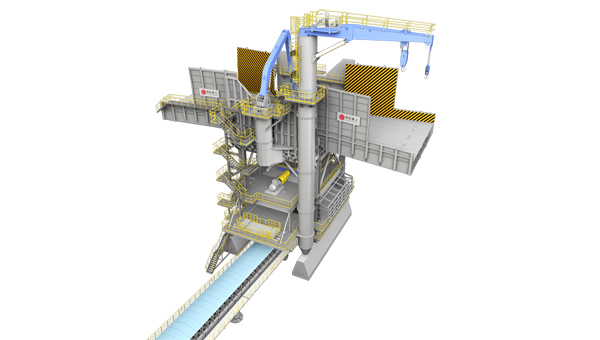

- Name of Client: Sampyo Cement Industrial

- Project: Limestone Project

- Location: South Korea

- Crusher Model: CC500

- Material: Limestone

- Capacity: 7.5 million tons / year

- Year of Manufacture: 2020

- Name of Client: Shandong Gold Group

- Project: Ghana Namdini Gold Project

- Location: Ghana

- Crusher Model: CC400

- Material: Gold

- Capacity: 10 million tons / year

- Year of Manufacture: 2023

-

Manufacturing

ManufacturingCasting and Forging Capacity

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively. -

Service

ServiceLifetime service

With state-of-the-art technology and rich experience, CITIC HIC works through each critical step to individualize the optimal process and performance as per customer needs. Our lifetime service covers equipment installation, testing, maintenance, refurbishing, remote monitoring & diagnosis, upgrading & retrofitting, and performance guarantee.