- Casting and Forging Capacity

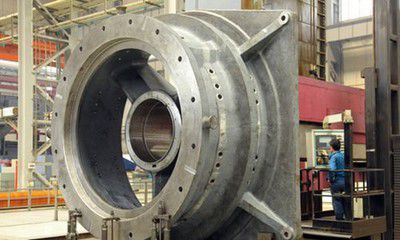

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively.

With one process, we are capable of achieving;

- refined molten steel of 900t,

- the largest steel ingot of 600t,

- the largest cast part of 600t,

- the largest forged part of 400t,

- the largest grey iron part of 200t,

- the largest ductile iron part of 150t,

- and the largest non-ferrous cast part of 20t.

- Fabrication capacity

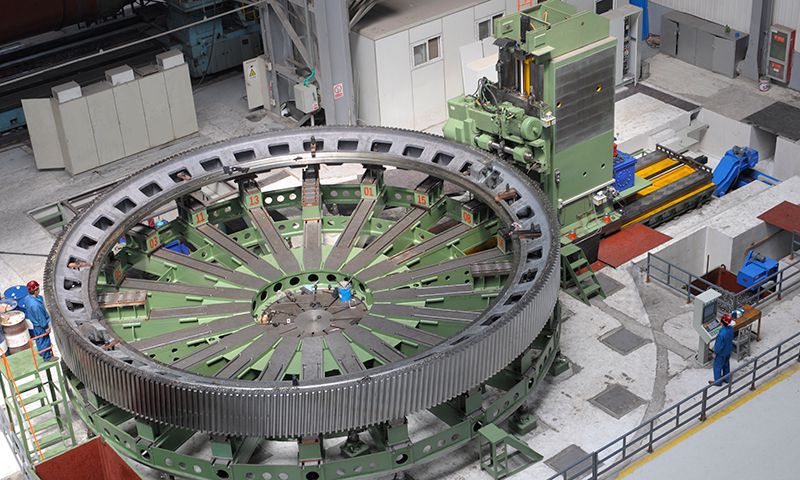

Our large heavy metal components workshop can produce 100,000 tons of riveted and welded parts per year. - Machining capacity

Our machining workshop is equipped with over 70 of the world's largest and most advanced CNC machine tools and gear processing equipment, 30 large CNC gantry boring and milling machines and floor type boring and milling machines, and nearly 3000 units of other various machine tools required for accurate quality production of our products.

We manufacture key components in-house

We introduced world advanced computer simulation software to model, simulate and analyze material, casting, forging and heat treatment to assure the quality of key parts of our products.