For over 60 years of experience in the mineral processing industry, CITIC Heavy Industries (CITIC HIC) has been always committed to increase the grinding efficiency of minerals by constantly searching for ways to improve and develop energy-saving high-efficiency ore grinding equipment. CSM series vertical stirred mill was jointly developed by a combined R&D team of foreign and domestic experts. With independent intellectual property right, this vertical stirred mill is an ideal wet grinding solution for global customers who are looking for safe, reliable and energy efficient stirred milling machines.

Vertical stirred mills are a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle. The significant advantages that the vertical stirred mills have over the ball mills are smaller size, less auxiliary equipment required, more simple system and more options of processing methods. Powder flow behaves continuously in the stirred mill, and it can be operated in both open- and closed-circuit operation.

Vertical stirred mills are also characterized by low noise, vibration and heat that are generated. The grinding media moves orderly in the vertically stirred media mill thereby resulting in more efficiency on grinding performance and much less power consumption. Since it is operated with wet grinding method, the vertical stirred mill does not require any cooling system due to the low speed operation.

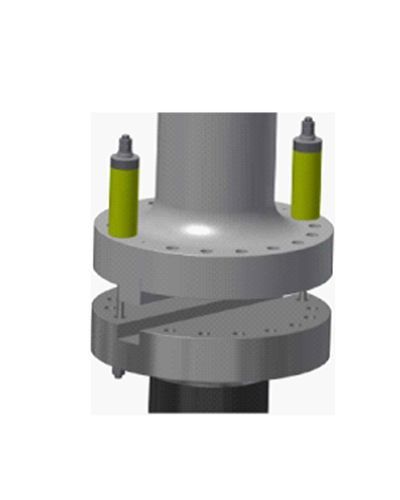

In addition, vertical stirred mill features a small footprint without any external rotating parts. The helical agitator achieves the force balance, enabling the foundation to bear only the combined forces of mill, slurry and grinding media. This simple foundation contributes in a short installation period.

- Small footprint

- No any external rotating parts

- Less auxiliary equipment required

- Simple foundation

- Easy installation, short installation period

- High efficiency, energy saving

- Low wear ratio, less cost

- Minimal maintenance

- Strong adaptability to ore characteristics

- Adjustable fineness of grind

- Good normal distribution

- More options of system

- Low rotation speed, high reliability

- Low low noise, vibration and heat

- High cost-effectiveness

CITIC HIC has participated in setting China National Standards of vertical stirred mills, leading the large-scale and intelligent development of stirred milling technology in the domestic market. Introducing world's advanced design and manufacturing standards, CITIC HIC ensures that the vertical stirred mill at the forefront of technical performance. Therefore, our customers can purchase complete sets of equipment from one source. - High operating rate

The long life cycle of our products is based on the adoption of international standards, high-quality materials, state-of-the-art processing techniques. - Low-carbon & environmental-friendly processes

A number of patented and intelligent control technologies coupled with long-life wear-resistant materials contribute in improved equipment performance, as well as low-carbon eco-friendly operations. - High-efficiency service

CITIC HIC's vertical stirred mills are widely used in non-ferrous metal, black coal and chemical mines for domestic mining companies and concentrators, and have been exported to Australia, Chile, Russia and more countries and regions all over the world. The reliable performance is particularly appreciated by our customers worldwide.

- Selection

-

Offering mining concentrator plants with different options of complete sets of equipment:

SAG mill (semi-autogenous mill) + ball mill + vertical stirred mill

High pressure grinding roll + ball mill + vertical stirred mill

High pressure grinding roll + vertical stirred mill

SAG mill (semi-autogenous mill) + vertical stirred mill

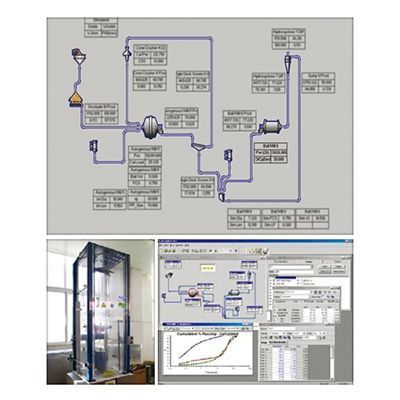

Providing the best solution of vertical stirred mill selection through minerals testing, process simulation and optimization

- Simulation

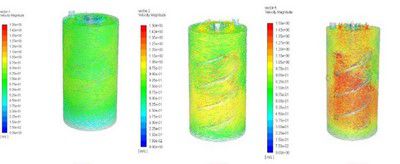

- With finite element analysis modeling, simulation analysis of coupling behavior between particle and fluid is carried out to optimize equipment operating parameters thereby increasing grinding efficiency.

- Strength

- Finite element analysis is employed for strength calculation of helical agitator, transmission shaft, barrel and upper body to identify the optimal structure, and seismic analysis is performed to ensure the reliability of the stirred mill.

- Transmission

- Three transmission modes are available according to the motor power:

Direct starting with squirrel cage motor

Variable frequency starting with VFD

Liquid resistance soft starting with wound rotor motor

- Auxiliary equipment

- Our vertical stirred mill can be configured with helical path unit, jacking system, spiral conveyor, hydraulic wrench, grinding media adding unit, etc.

- Control

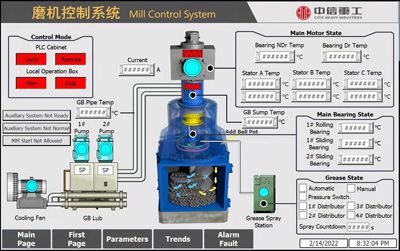

- PLC system is adopted to achieve low-pressure control and system protection. Monitoring system is used to visually inform the operator of the system status including temperature, pressure, flow rate, pressure difference and vibration rate via touc screen display.

| Model | Motor power | Required floor space | Height | Fresh feed capacity | |

| kW | HP | m×m | m | t/h | |

| CSM-150 |

150 | 200 | 2.4×2.5 | 9 | 13~16 |

| CSM-200 |

200 | 268 | 2.4×2.5 | 9.2 | 18~21 |

| CSM-250 |

250 | 335 | 2.7×2.8 | 9.6 | 22~27 |

| CSM-300 |

300 | 400 | 3.1×3.2 | 10.1 | 27~32 |

| CSM-400 |

400 | 536 | 3.2×3.4 | 11.9 | 36~44 |

| CSM-500 |

500 | 670 | 3.6×3.8 | 12.1 | 46~56 |

| CSM-600 |

600 | 800 | 3.7×3.9 | 12.7 | 56~67 |

| CSM-750 |

750 | 1000 | 3.9×4.1 | 13 | 71~85 |

| CSM-850 |

850 | 1150 | 4.2×4.5 | 13.5 | 81~97 |

| CSM-1000 |

1000 | 1350 | 4.3×4.6 | 13.8 | 96~115 |

| CSM-1120 |

1120 | 1500 | 4.4×4.7 | 14.3 | 107~129 |

| CSM-1300 |

1300 | 1750 | 4.6×5.1 | 14.4 | 125~150 |

| CSM-1500 |

1500 | 2000 | 4.9×5.3 | 14.8 | 144~173 |

| CSM-1700 |

1700 | 2250 | 5.2×5.4 | 16.2 | 163~196 |

| CSM-2250 |

2250 | 3000 | 5.8×6.2 | 17.8 | 216~260 |

| CSM-2750 |

2750 | 3690 | 6.8×7.1 | 18.2 | 269~323 |

| CSM-3360 |

3360 | 4500 | 6.8×7.1 | 19.3 | 323~388 |

| CSM-5300 |

5300 | 7000 | 8.2×8.6 | 20.4 | 510~612 |

Notes: The above table is based on that 60 percent of feed particles are in minus 200-mesh size, the grind fineness of 80 percent is minus 400-mesh size.

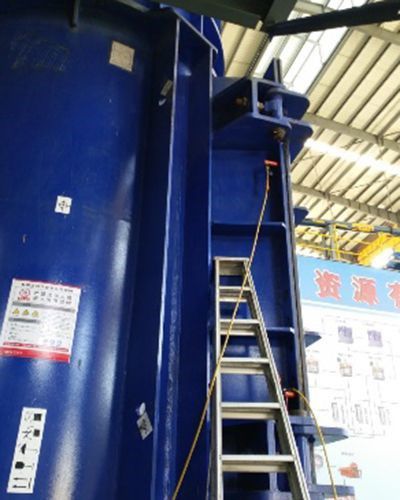

Chilean State Owned Copper Mining Company (Codelco)

Vertical stirred mill (CSM-1200)

Zijin Mining Group

CSM-1120Vertical Stirred Mills

Jiuquan Iron and Steel Company (JISCO)

Vertical stirred mill (CSM-1120)

TISCO Group

Vertical stirred mill (CSM-1120)

-

Manufacturing

ManufacturingCasting and Forging Capacity

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively. -

Service

ServiceLifetime service

With state-of-the-art technology and rich experience, CITIC HIC works through each critical step to individualize the optimal process and performance as per customer needs. Our lifetime service covers equipment installation, testing, maintenance, refurbishing, remote monitoring & diagnosis, upgrading & retrofitting, and performance guarantee.