With over 60 years of innovation and development, CITIC HIC has become the world’s most competitive supplier of crushing equipment and an integrated crushing solutions provider. Our comprehensive range of crushing equipment includes gyratory crushers, semi-mobile crushing stations, single-cylinder cone crushers, multi-cylinder cone crushers, jaw crushers, and sizer crushers.

- Proven Reliability: We have established a strong track record with over 200 units of large-scale gyratory crusher, cone crusher, jaw crusher, and sizer crusher successfully used in metal mining and aggregate processing operations worldwide.

- Industry-Leading Technology: Leveraging years of application experience and technical expertise in both mining and aggregate processing, CITIC HIC has achieved significant advancements in research, development, and practical implementation. Our comprehensive technical indicators, encompassing equipment reliability, process performance, intelligent features, service and maintenance, and the continuous optimized supply of spare parts, have reached international advanced levels.

- Global Reach: CITIC HIC crushers have been successfully applied to major mining projects across the globe, including clients such as VALE (Brazil), LKAB (Sweden), CODELCO (Chile), Gerald Group (Ghana), and Sampyo (South Korea), in operations such as iron ore, copper, gold, and molybdenum mining, as well as granite and pyroxenite crushing.

Our crushers and crushing solutions are designed and manufactured to the highest international standards, ensuring maximum operational efficiency, reliability, and cost-effectiveness.

-

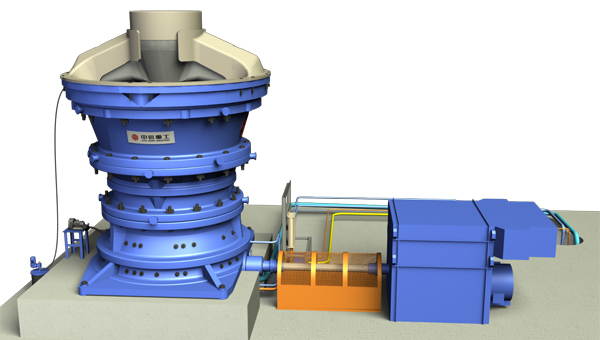

Gyratory Crusher

The PXZ series gyratory crushers are designed for primary crushing applications, with models capable of handling capacities from 1000 to 17000 tons per hour. These crushers are characterized by their high throughput, high crushing efficiency, large reduction ratio, uniform product size, low power consumption, and even wear within the crushing chamber.

-

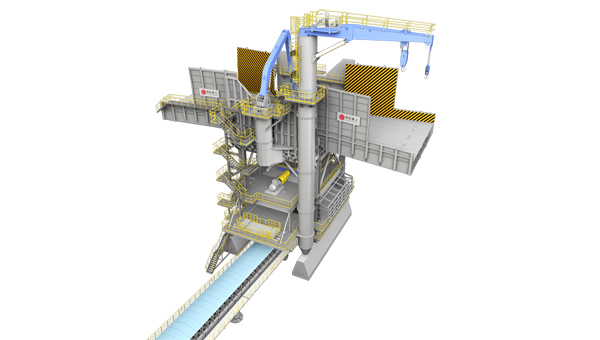

Semi-Mobile Crushing Station

The semi-mobile crushing station utilizes gyratory, jaw, or sizer crushers as the primary crushing equipment, integrated with steel structure-based application platforms. These stations are also equipped with essential operation and maintenance equipment, including belt conveyors, rock breakers, jib cranes (overhead cranes), and dust suppression systems.

-

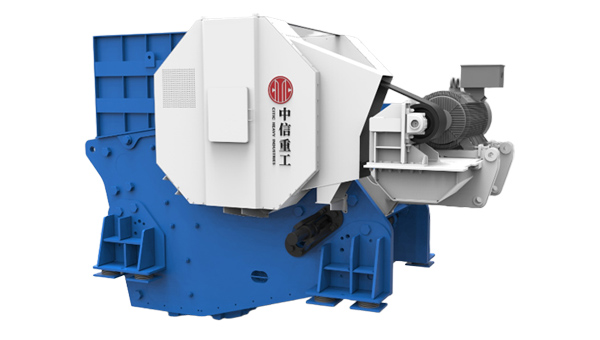

Jaw Crusher

The PE series jaw crusher is engineered to meet the demands of crushing systems with capacities ranging from 300 to 1500 tons per hour. The entire series features a hydraulic tensioning system and automatic discharge opening adjustment. Utilizing the most advanced deep V-shaped cavity design concept and optimized kinematic characteristics, these crushers maximize crushing efficiency and significantly extend the lifespan of the liners.

-

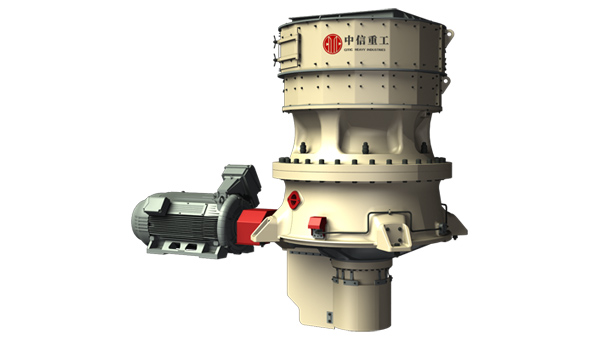

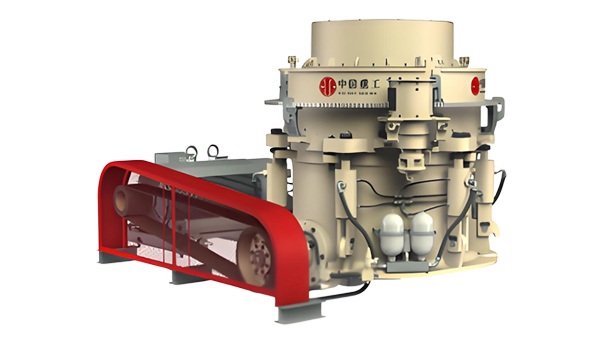

Single-Cylinder Hydraulic Cone Crusher

The CCS series single-cylinder cone crusher is widely used for secondary and fine crushing operations, with models catering to capacities from 500 to 1800 tons per hour. Integrated with our in-house designed and manufactured complete hydraulic lubrication station and AICS intelligent control system...

-

Multi-Cylinder Hydraulic Cone Crusher

The CC series multi-cylinder hydraulic cone crusher is primarily used for secondary and fine crushing of various high and medium-hard materials. Featuring a large eccentric throw and high swing speed design, it delivers greater crushing force. Combined with an optimized cavity design, the equipment's processing capacity and crushing efficiency are enhanced...

-

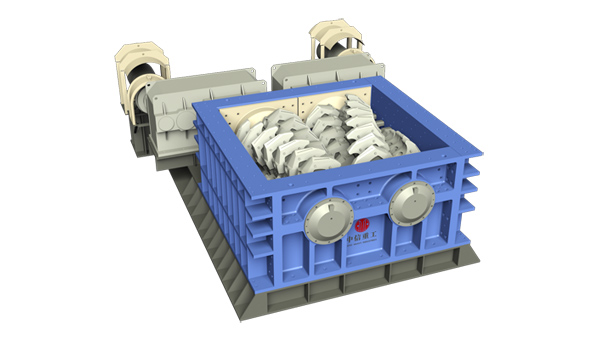

Sizer Crusher

The sizer crusher can meet the requirements of crushing systems with a maximum capacity of 10,000 tons per hour. We have achieved the research, development, and manufacturing capabilities for ten-thousand-ton-per-hour sizer crushing stations. Our sizer crushers have been successfully applied in various fields, including open-pit coal mines...