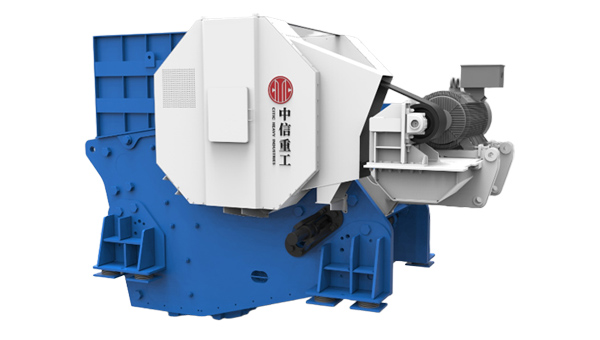

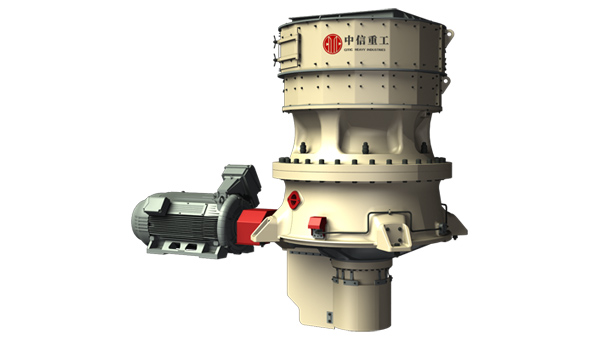

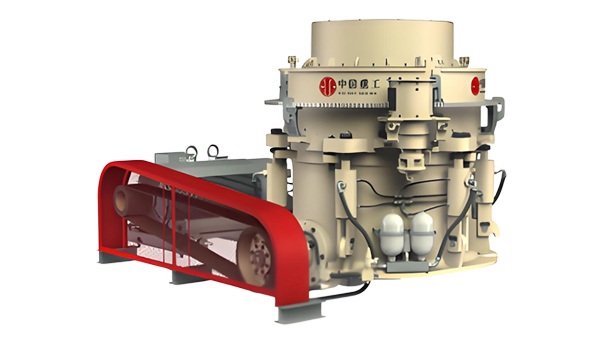

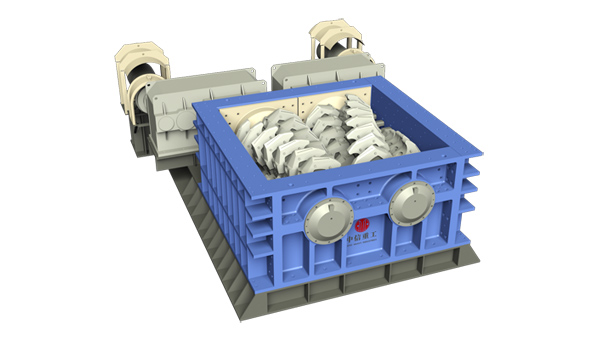

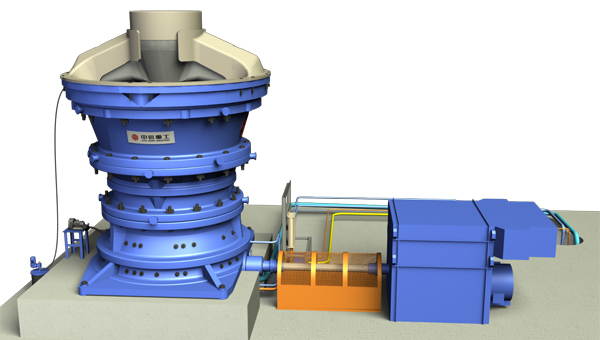

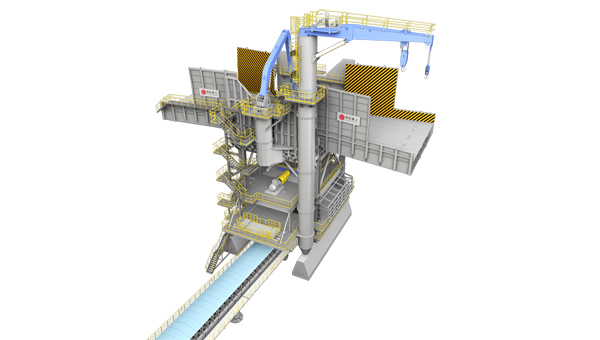

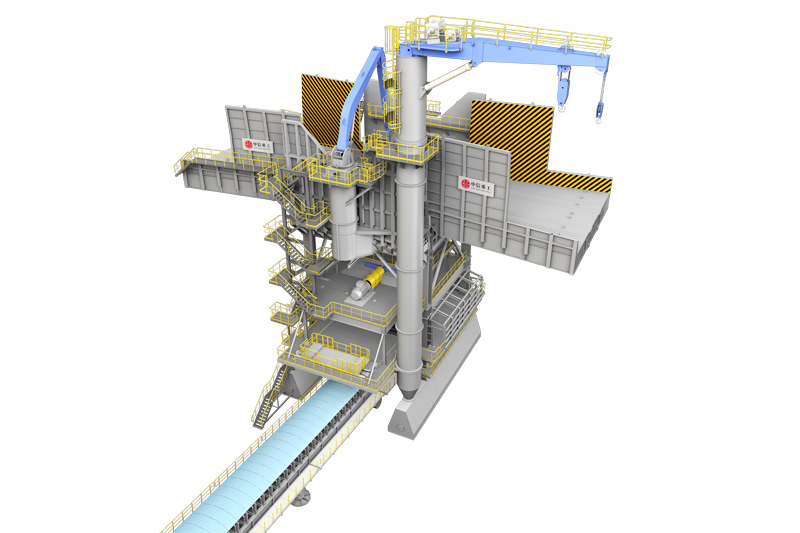

The semi-mobile crushing station utilizes gyratory, jaw, or sizer crushers as the primary crushing equipment, integrated with steel structure-based application platforms. These stations are also equipped with essential operation and maintenance equipment, including belt conveyors, rock breakers, jib cranes (overhead cranes), and dust suppression systems. Through a well-designed overall layout and configuration, a highly integrated crushing station system is formed. This system seamlessly coordinates technologies across various stages, from feeding and crushing to lubrication, dust prevention, spraying dust suppression, installation, maintenance, discharging, conveying, iron removal, and relocation. Featuring intelligent operation and control, and offering convenient and rapid mobility, these semi-mobile stations meet the demands of high-efficiency operations in open-pit metal mines.

- Flexible configuration: The crushing station’s modular design integrates key components like feeding, crushing, lubrication, and dust prevention systems, ensuring seamless operation.

- Intelligent operation and control: The station features smart technology that allows for efficient control of processes and operations.

- Efficient mobile solution: The semi-mobile design allows for easy transport and quick setup, making it ideal for open-pit mining operations.

- Comprehensive support equipment: Includes spraying dust suppression, iron removal, conveying, and maintenance equipment, optimizing productivity and ensuring minimal downtime.

- High efficiency in open-pit mining: Designed to meet the demanding operational requirements of large-scale metal mining, enhancing the overall performance and output of mining operations.

| Model | ||||||||||

| Capacity (t/h) | 1500-2950 | 2880-4450 | 4200-6500 | 5530-8590 | 7500-15000 | |||||

| Recommended feed size (mm) | 900-1000 | 1100-1400 | 1200-1400 | 1200 | 1200-1400 | |||||

| Crusher model | PXZ42-65 | PXZ54-75 | PXZ60-89 | PXZ60-110 | PXZ63-130 | |||||

| PXZ50-65 | PXZ62-75 | PXZ70-89 | PXZ60-113 | PXZ72-130 | ||||||

| Feed opening (mm) | 1100/1270 | 1375/1600 | 1525/1780 | 1525 | 1600/1830 | |||||

| Belt conveyor capacity (t/h ) | ≥2500 | ≥4000 | ≥6000 | ≥9000 | ≥15000 | |||||

| Jib crane | Main hook | 50t | Main hook | 70t | Main hook | 80t | Main hook | 125t | Main hook | 150t |

| Auxiliary hook | 10t | Auxiliary hook | 20t | Auxiliary hook | 20t | Auxiliary hook | 20t | Auxiliary hook | 20t | |

Note1: Actual production capacity depends on the actual processing circuit and ore properties. The capacity values above are calculated based on a bulk density of 1.6t/m³ and medium hardness ores.

Note2: The above parameters are for reference only and are subject to detailed engineering.

- Name of Client: LKAB

- Project: Mertain Mine

- Location: Sweden

- Crusher Model: PSZ3000-B

- Material: Iron

- Capacity: 20 million tons / year

- Year of Manufacture: 2013

- Name of Client: LKAB

- Project: Leveaniemi Mine

- Location: Sweden

- Crusher Model: PSZ3000-B

- Material: Iron

- Capacity: 20 million tons / year

- Year of Manufacture: 2014

- Name of Client: Northern International Group

- Project: Laibitang Copper Mine

- Location: Burma

- Crusher Model: PSZ4000-B

- Material: Copper

- Capacity: 40 million tons / year

- Year of Manufacture: 2012

- Name of Client: China Nonferrous Group

- Project: Deziwa Mine

- Location: DRC

- Crusher Model: PSZ2000-B

- Material: Copper & Cobalt

- Capacity: 6 million tons / year

- Year of Manufacture: 2018

-

Manufacturing

ManufacturingCasting and Forging Capacity

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively. -

Service

ServiceLifetime service

With state-of-the-art technology and rich experience, CITIC HIC works through each critical step to individualize the optimal process and performance as per customer needs. Our lifetime service covers equipment installation, testing, maintenance, refurbishing, remote monitoring & diagnosis, upgrading & retrofitting, and performance guarantee.