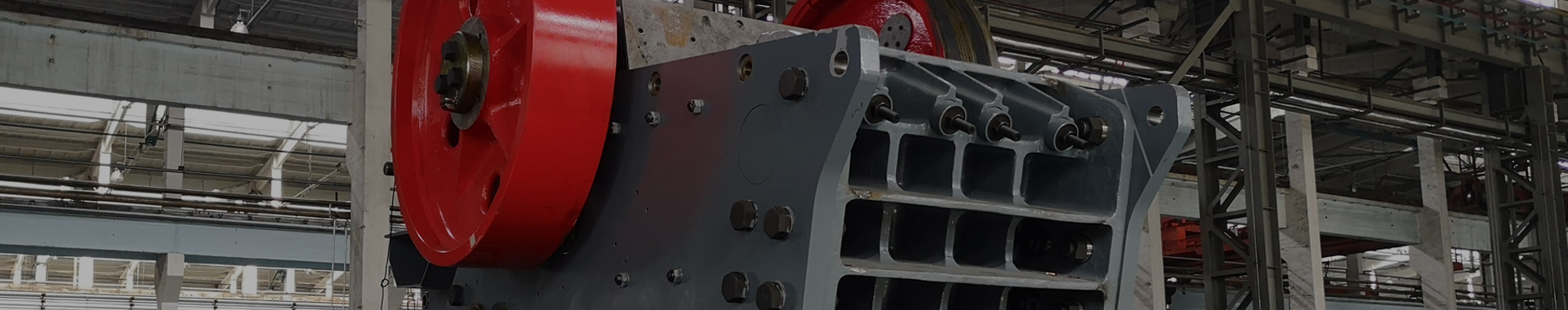

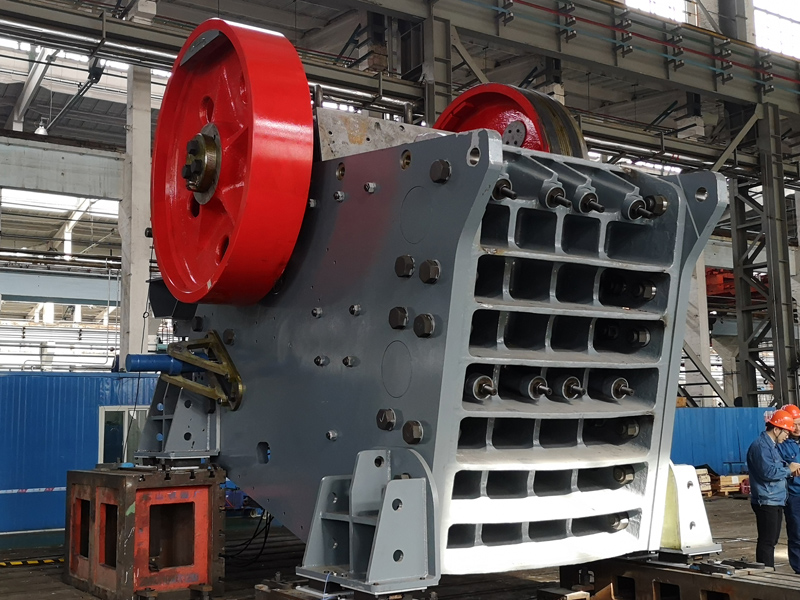

The PE series jaw crusher is engineered to meet the demands of crushing systems with capacities ranging from 300 to 1500 tons per hour. The entire series features a hydraulic tensioning system and automatic discharge opening adjustment. Utilizing the most advanced deep V-shaped cavity design concept and optimized kinematic characteristics, these crushers maximize crushing efficiency and significantly extend the lifespan of the liners. Proven in numerous applications worldwide, including the common 1500x2000 specification.

- High capacity: Handles throughputs from 300 to 1500 t/h.

- Hydraulic tensioning: Ensures consistent crushing force and efficient operation.

- Automatic discharge adjustment: Allows for easy and precise control of the output size.

- Deep V-shaped cavity: Maximizes crushing efficiency and material throughput.

- Optimized kinematics: Enhances crushing action and reduces energy consumption.

- Extended liner life: Minimizes downtime and replacement costs.

- Proven Performance: Successfully implemented in various global applications.

| Model | Feed opening (mm) | Max. feed size (mm) | Closed side setting (mm) | Motor power (kW) | Capacity (t/h) |

| | 510×800 | 400 | 50-175 | 75 | 70-350 |

| | 580×930 | 500 | 60-175 | 90 | 120-420 |

| | 760×1000 | 600 | 70-200 | 110 | 150-500 |

| | 850×1100 | 700 | 70-200 | 160 | 180-600 |

| | 950×1250 | 800 | 100-250 | 160 | 280-810 |

| | 1100×1200 | 900 | 125-275 | 185 | 330-850 |

| | 1100×1400 | 900 | 125-275 | 200 | 380-1050 |

| | 1200×1400 | 1000 | 125-250 | 200 | 360-900 |

| | 1200×1600 | 1000 | 150-300 | 250 | 480-1100 |

| | 1300×1700 | 1100 | 150-300 | 300 | 520-1250 |

| | 1500×2000 | 1200 | 175-300 | 400 | 720-1500 |

Note1: Actual production capacity depends on the actual processing circuit and ore properties. The capacity values above are calculated based on a bulk density of 1.6t/m³ and medium hardness ores.

Note2: The above parameters are for reference only and are subject to detailed engineering.

- Name of Client: Hubei E Dong Mining Group

- Project: Yangxin Dazhangshan

- Location: China

- Crusher Model: PE1500x2000

- Motor power: 400kW

- Material: Aggregate

- Capacity: 8.5 million tons / year

- Year of Manufacture: 2024

- Name of Client: Conch Group

- Project: Hainan Changjiang

- Location: China

- Crusher Model: PE1500x2000

- Motor power: 400kW

- Material: Aggregate

- Capacity: 4 million tons / year

- Year of Manufacture: 2019

- Name of Client: Jiangxi Copper Group

- Project: Cheng Menshan Project

- Location: China

- Crusher Model: PE1200x1400

- Material: Copper

- Capacity: 4.5 million tons / year

- Year of Manufacture: 2021

-

Manufacturing

ManufacturingCasting and Forging Capacity

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively. -

Service

ServiceLifetime service

With state-of-the-art technology and rich experience, CITIC HIC works through each critical step to individualize the optimal process and performance as per customer needs. Our lifetime service covers equipment installation, testing, maintenance, refurbishing, remote monitoring & diagnosis, upgrading & retrofitting, and performance guarantee.